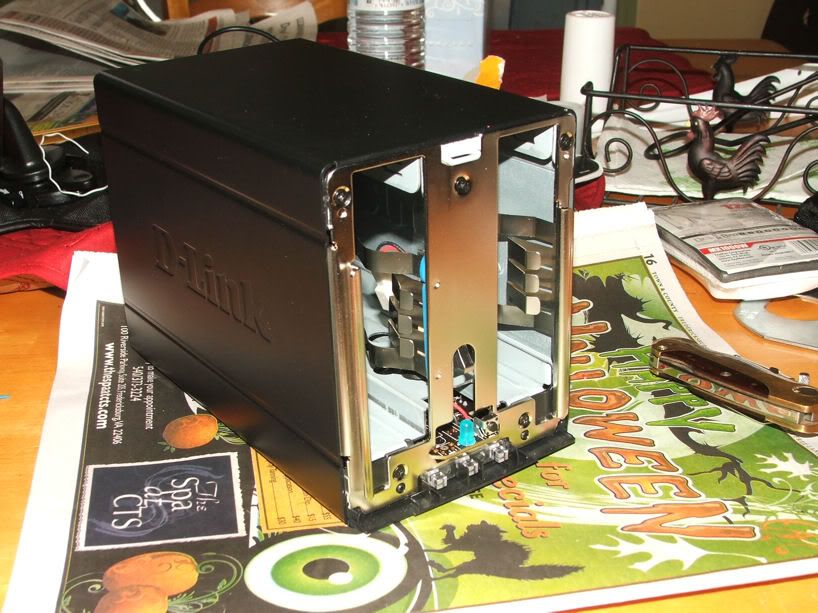

D-Link DNS-321 Auto Power On Hardware Modification

[Disclaimer: You void your warrantee if you perform this modification. You also take a chance to damage your NAS if you are not handy with a soldering iron. If you damage your NAS, don't come running to me. I have performed this modification on my Rev A2 unit (note the silk screen board states it's a Rev A1).]

Please read the entire document before tearing apart your NAS.

Before you start, one thing to note is that if you turn off your NAS, if you should have a power loss the NAS will start up when power returns. I can't help that being this is a simple circuit. The work around is to have a enable/disable switch like I have integrated here.

Parts required:1) Capacitor (220uf to 800uf @ 5VDC to 25VDC)

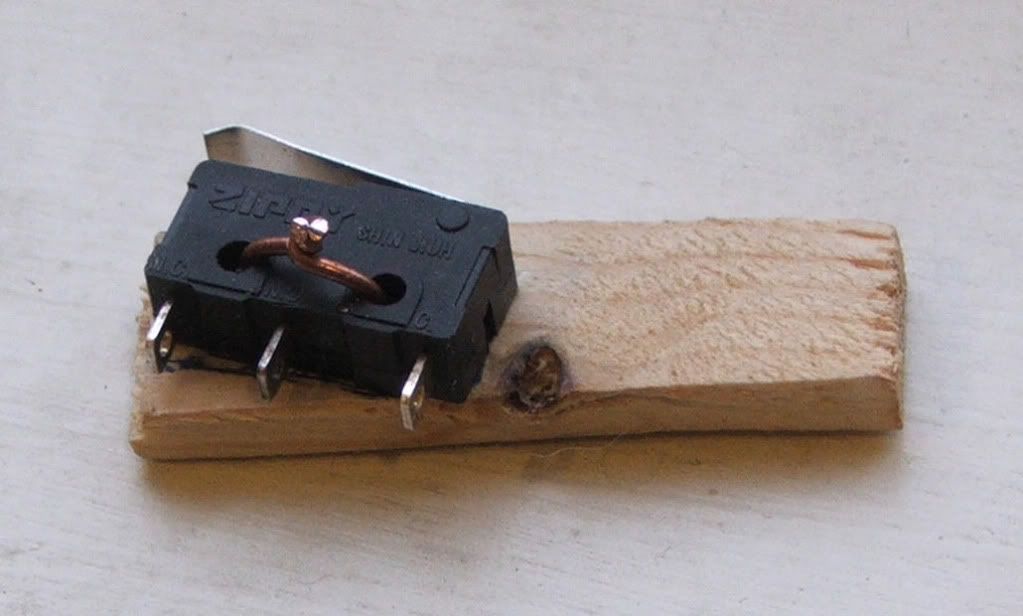

2) Enable/Disable switch. (I used a submini lever switch P/N: 275-016A, AKA microswitch) (Not required)

3) Small gauge insulated wire

4) Rubber Grommet

5) Quick Disconnect (this is a handy item to have but not required)

5) Solder & soldering iron (15 watts)

6) Patience and a plan of attack.

Getting inside the DNS-3211) Remove the front cover.

2) Remove any hard drives installed and note which slot they were in.

3) Remove 5 screws securing the silver drive guide and set to the side.

4) Remove the rear top outer screws securing the back of the case to the outer frame.

5) Remove the 6 bottom screws. Note that there screws are different from the others.

6) Gently push the bottom up and towards the rear. The top should easily separate from the bottom.

7) Remove two screws in the inside rear which secures the metal frame to the SATA sockets.

Remove the 4 screws securing the metal frame to the bottom.

WARNING: The circuit board is now loose however the rear SATA connectors are not. If you are going to remove the board you must remove the 4 remaining screws holding the SATA connectors in place.

9) Carefully remove the metal frame.

Modification

ModificationIn my rendition I used the front cover, when lifted to disable my circuit. This is how I will discuss the installation.

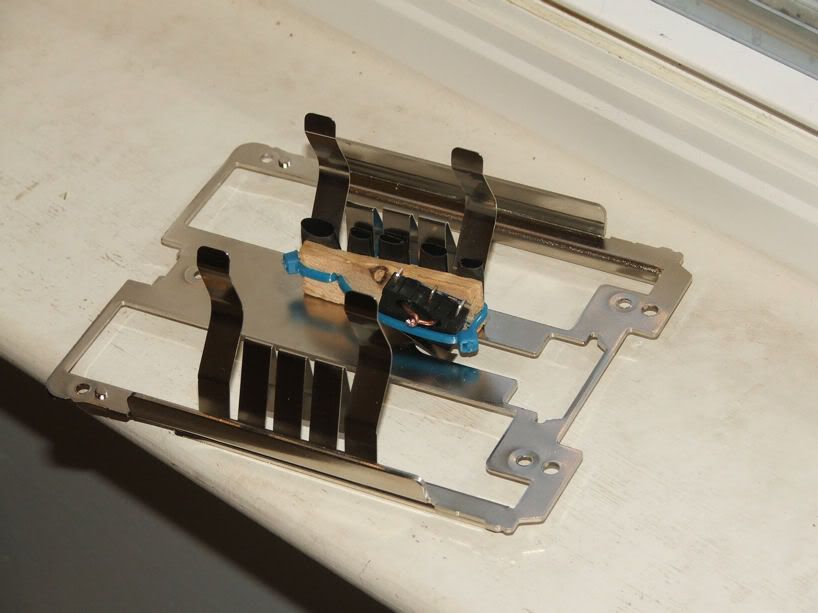

1) Dry fit your enable/disable switch, if you're using one. As mentioned before, I used a microswitch and I needed a spacer so I could center it in the groove. Since I didn't have very small wood screws to secure the switch to the spacer I opted to use some 12GA left over copper wire. To keep the wood spacer from moving around I used my cheap version of double sided sticky tape (rolled electrical tape). And I used small tie wraps. When the front access door is opened up 1/2 inch, the microswitch opens the circuit and the Auto Power On feature is disabled. Make sure you use the door to verify proper operation. I had to bend my lever so it would activate the switch properly and ride smoothly on the plastic.

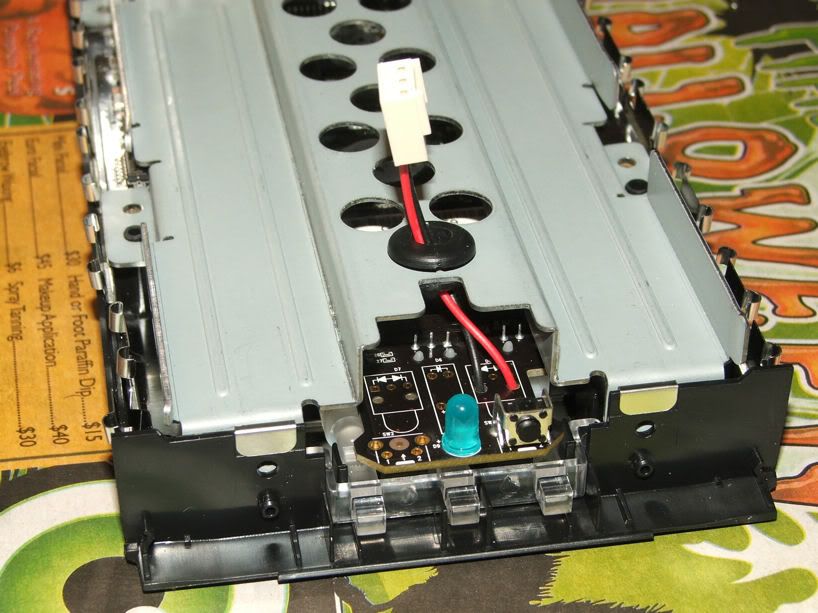

2) Dry fit your capacitor. I didn't know the final placement until I mounted the switch (see later photos for my placement), it was then that I noticed I could mount it the way I did and eliminate one wire. In my version, the negative lead of the capacitor connects (pressed against) the metal spring. The entire unit, all metal frames are connected together and connected to the electrical ground so it saves us one wire to be routed. You can of course route a separate ground wire if you like.

3) Mount your components. Do not apply too much pressure to the capacitor. If you do then you could short it out and you will wonder why the on/off switch doesn't work anymore. If you're happy with the dry fit and it's easy to solder on those parts, mount them in place or if you need to do a little soldering, do that first.

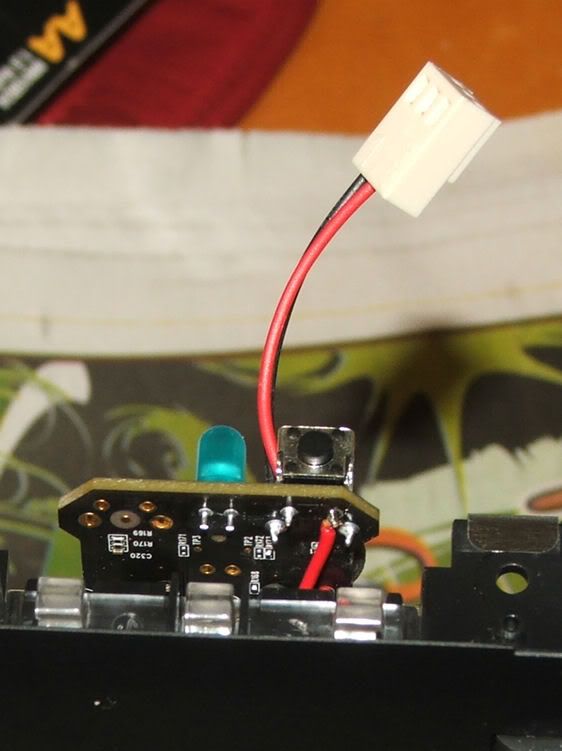

4) Now it's time to solder the wire (I used an old 3 wire fan extension, red wire hot, black wire as an extra strain relief). Since the frame is so sharp you need to use a grommet to protect the wire. In my situation I had to run the wires through the grommet first, fish the wire through the unused holes, tied a single knot in each wire so it acts as a strain relief, and then solder the red wire in place. The black wire is not connected, it's only used as an extra strain relief. Be careful when doing this step because it's really the only part you could mess up. If you solder to the wrong spot, it just won't work but you won't damage the NAS.

5) Now push that rubber grommet through one of the inner frame holes. Note: a little saliva goes a long ways for lubricating a hard to insert grommet. I've said this one so I'll repeat it... The entire inner frame has sharp edges and you're taking a risk if you don't provide adequate protection for the wire. Remember, this device vibrates and those little movements will wear through thin insulation.

6) We will solder the end of the wire to the switch after we reassemble the NAS. Reverse the process above for putting the NAS back together but stop before putting the front metal plate with the switch.

7) Lay the metal plate in front of the NAS box and using the other end of the 3 wire fan extension, measure just enough wire so you can hold on to both ends and detach it. Too much wire means you need to pay special attention when installing drives to keep from hanging on them. Cut the wires and solder them to the switch. I soldered the red wire to the microswitch and the black to the copper wire, again to act as a strain relief. Unfortunately my connectors do not easily slide apart, a little force is required so I'm making it a little more robust.

Install the front plate. Note in the first photo that the tie wrap would interfere with the drive pressure spring (caught it before installing a drive) so I have to cut that out and reposition a new tie wrap.

9) Install the front cover. This photo shows all I need to do to disable the auto power on.

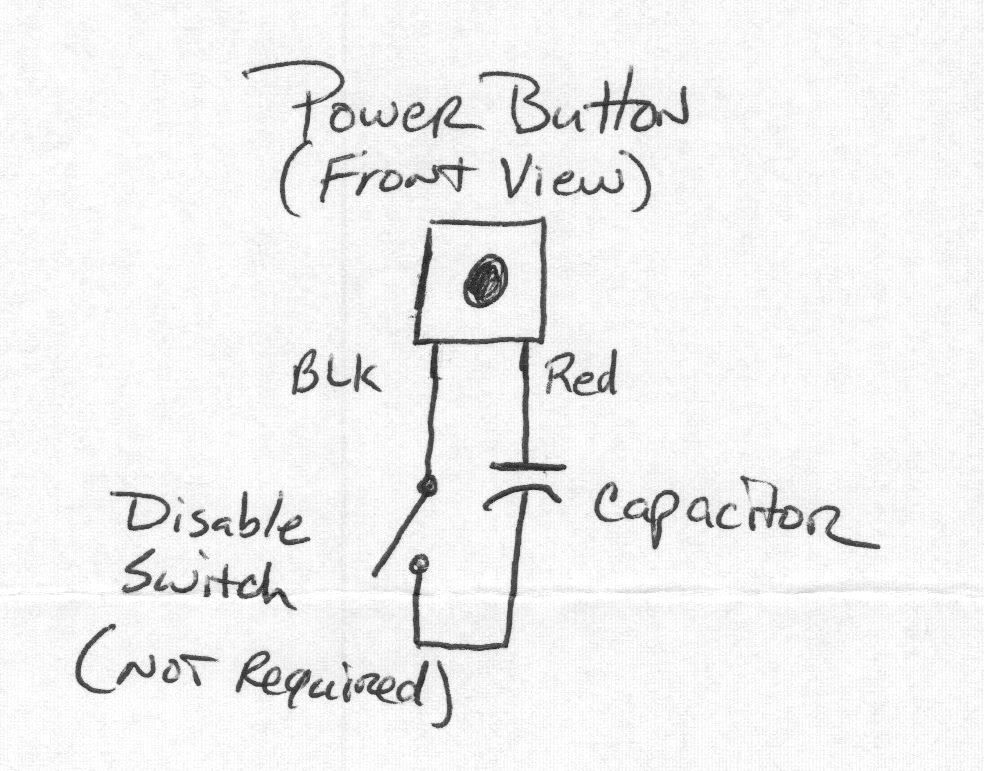

And a schematic that I totally forgot. It's crude but it gets the job done (sorry it's so big).

Testing

Testing1) With your power supply brick unplugged from the wall, connect it to the NAS.

2) Plug in the power supply. The unit should power up.

3) Unplug the power supply from the wall.

4) Lift up the front cover to disable the Auto Power On feature.

5) Plug in the power supply. The unit should remain off.

6) Wait until the unit is "Ready" and close the cover to enable the circuit. The unit should not turn off. If it does, it's possible the capacitor it too large a uf value and possibly bad.

7) Turn off the NAS using the On/Off button.

Turn on the NAS using the On/Off button.

9) Log in to your NAS configuration page. If that works I think you're ready to turn off your NAS and reinstall the hard drives. Remember to place them in the same location.

10) Turn on your NAS and ensure it works like normal.

-Joe

Author

Topic: Auto Power On - Minor Hardware Modification (Read 30688 times)

Author

Topic: Auto Power On - Minor Hardware Modification (Read 30688 times)